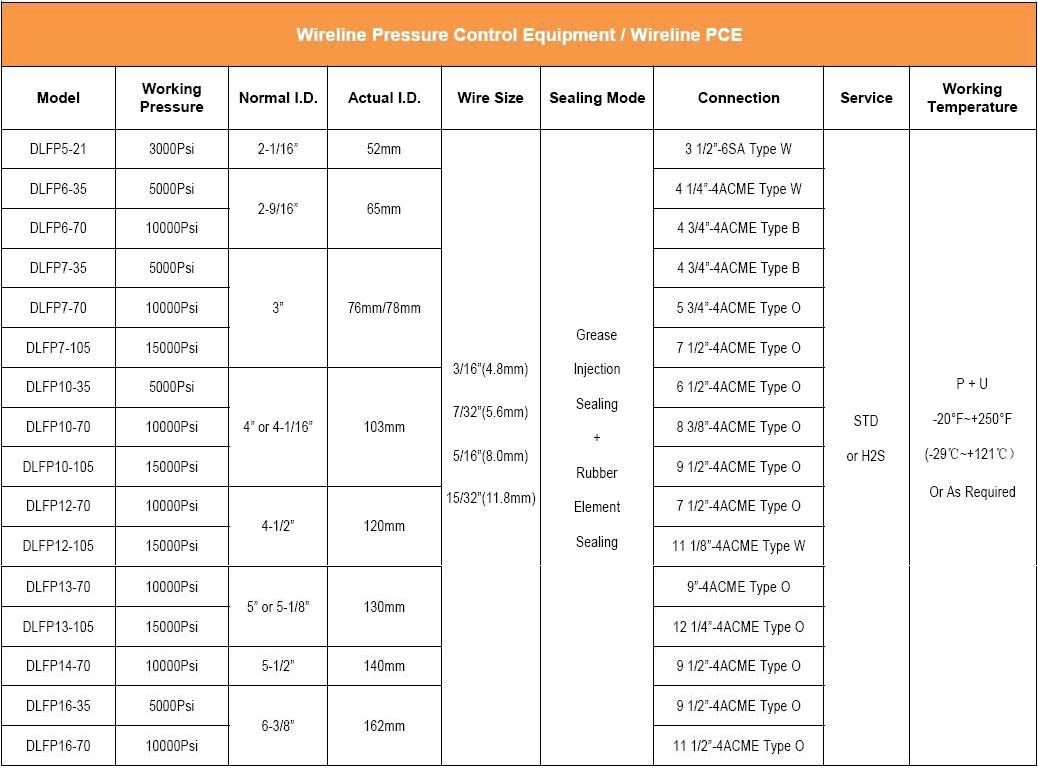

Popular Name: Wireline Pressure Control Equipment / Wireline PCE/ WPCE

Wireline Pressure Control Equipment ( abbr. Wireline PCE or WPCE ) could be applied for lot of oil & gas operation. Such as Testing, Logging, Paraffin Removal, Fracturing & Perforation in Flowing Oil Well, Gas Well, Water Injection Well, Coalbed Methane Testing and Shale gas operation, etc. The unit providing pressure buffer and transition area for Tool String running into the hole under pressure. It can prevent blowout accidents by sealing the wellhead no matter the wire dynamic or static during operation, or closing the wellhead when the wellhead overflow is out of control or any other accident occurs during operation.

Feature

1) The design and manufacturing of Wireline PCE Comply with API Spec-16A, API Spec-6A, NACE MR 0175 and other relevant standards.

2) Expertly engineered and rigorously tested.

3) Safety, Reliability and Good Service.

4) High Cost-effective.

5) Third Party Inspection allowed.

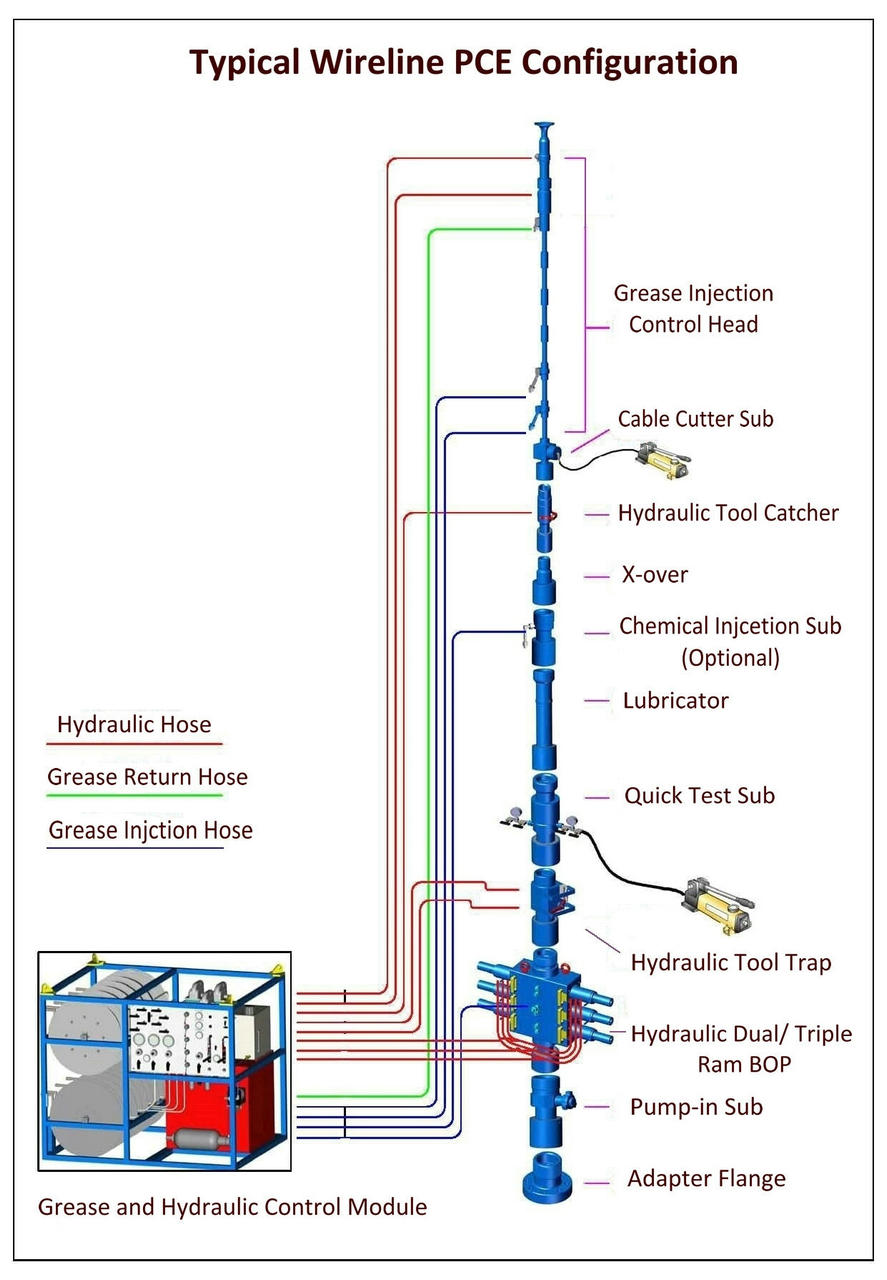

Wireline PCE String mainly be consist of

1) Wellhead Adaptor Flange

2) Pump-in Sub

3) Hydraulic Dual Ram BOP or Hydraulic Triple Ram BOP

4) Hydraulic Tool Trap

5) Quick Test Sub

6) Lubricator with Threaded Union or Lubricator with Integral Union

7) Hydraulic Tool Catcher & Ball Check Valve

8) X-over

9) Cable Cutter Sub

10) Wireline Grease Injection Control Head

11) Upper and Lower Sheave

12) Lifting Tool

13) Grease and Hydraulic Control Module

Note

1) There are Bowen (Type B), Otis (Type O) and our own Quick Union (Type W) for threaded selective.

2) Additional size available on request.

Package

A Transport Frame is recommended for a set of Wireline PCE. It could protect the whole WPCE effectively, reduce the damage and loss in transportation. And it easy for transport and lifting.

If you purchase the parts separately, It will be packaged in a wooden box or iron box according to the weight and dimension.

Normal Guarantee Period

12 months after the clients received the Equipment or 13 months after the Equipment is shipped from Chinese Harbor.

Information Required When Inquiry

1) Which parts do you needed? And quantity of each parts.

2) I.D. of main parts, such as Adapter Flange, BOP, Lubricators. If these parts have same I.D. , only provide one is OK. If they have different I.D. , please provide each details separately.

3) The wire size you will apply when operation.

4) Rated Working Pressure.

5) Single Ram BOP, Dual Ram BOP or Triple Ram BOP you required, and the Rams type you needed if it is Triple Ram BOP.

6) Required Working Temperature.

7) Service Environment. ( STD or H2S )