Popular Name:Pump-in Sub / Pump-in Tee / Flow Tee

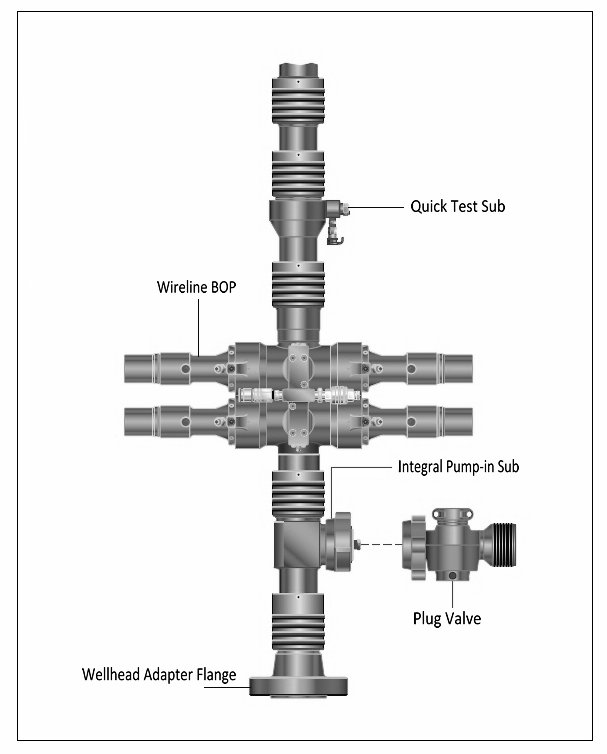

The Pump-in Sub is normally positioned below the Wireline BOP and above the wellhead. It has Quick Union top and bottom, and a WECO ( Hammer Union ) type side outlet. A Plug Valve will be applied to connect with the side outlet normally.

Pump-in Sub main function is to allow well control by pumping fluid below a closed Wireline BOP. Its is mainly used for the pumping fluid to wash well or bleed the residual liquid in Wireline PCE after the BOP has been closed.

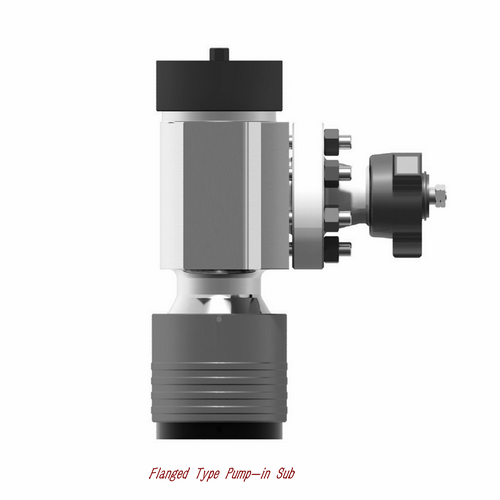

There are two kinds of structure Pump-in Sub. The main difference is the is the side outlet is integral or not.

Normally, we will provide with Integral Pump-in Sub if no special requirement.

Features

1) Two kinds of structure for selective. Integral Pump-in Sub is recommended.

2) One piece forging of the Tee Body, without welding.

3) The pressure-containing parts are made of high strength alloy steel with good corrosion resistance.

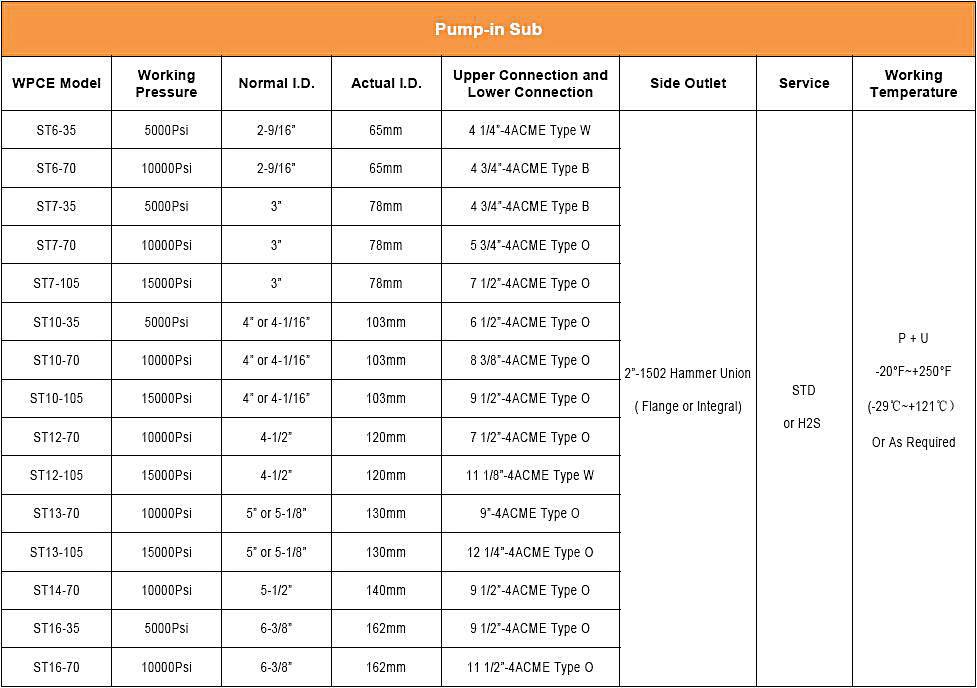

Main Parameter

1) I.D.

2) Working Pressure

3) Side out-let: 2”-1502 Hammer Union ( Flange or Integral)

4) Upper and Lower Union Required ( It is same to the BOP Normally )

5) Service Environment ( STD or H2S )

6) Working Temperature

Note

1) There are Bowen (Type B), Otis (Type O) and our own Quick Union (Type W) for threaded selective.

2) Additional size available on request.

Normal Guarantee Period

12 months after the clients received the Equipment or 13 months after the commodity is shipped from Chinese Harbor.

Information Required When Inquiry

If you will purchase the whole Wireline PCE, please refer to the Information Required When Inquiry in Chapter《Wireline PCE》.

If you purchase the Pump-in Sub separately, the Main Parameter information above mentioned will be asked.