Popular Name: Wireline BOP / Compact Wireline Valve / WLV

A Wireline BOP must always be installed between the wellhead and Wireline Lubricators. This BOP is a piece of Pressure Control Equipment that can close around the wire and seal off the well pressure below it. This enables the pressure to be bleed off above it, allowing work or repairs to be carried out on equipment above the BOP without pulling the Wireline Tools to surface. A positive seal is accomplished by means of rams, which are manually or hydraulically closed without causing damage to the wire.

Hydraulic Wireline BOPs are more commonly applied because of the speed of closing action and ease of operation. During an emergency, often the BOP is not easily accessible to allow fast manual operation and therefore hydraulically actuated is preferred.

Wireline BOPs are fitted with Balance Valves Assembly that allow Lubricator and well pressure to equalize prior to opening the Rams when Wireline operations are to be resumed. Without this, if the BOP Rams were to be opened without first equalizing the pressure surge could blow the Tool String or Wire into the top of the Lubricator, causing damage or breakage.

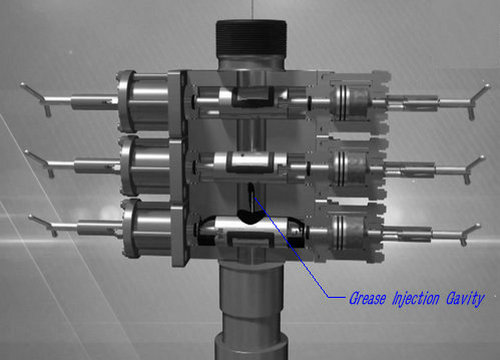

Single, Dual or Triple Ram BOP are available in various sizes and in a full range of working pressure ratings. Dual and Triple Rams offer increased safety during Wireline work and allow the injection of grease to secure a seal on Braided Wire.

Feature

1) The design and manufacturing of Wireline BOPs comply with API Spec-16A, NACE MR 0175 and other relevant standards.

2) Forged monobloc construction Body.

3) Compact size, allowing shorter rig-up heights.

4) Hydraulic Cylinder Slide Rods, allowing fast removal of Cylinder for Ram or Seal replacement.

5) Ram position indicator Rods for external indication of the Ram position.

6) Integral Balance Valve Assembly, chemical and grease injection.

Main Parameter

1) I.D.

2) Working Pressure

3) Single Ram BOP, Dual Ram BOP or Triple Ram BOP you required, and the Rams type you needed if it is Triple Ram BOP

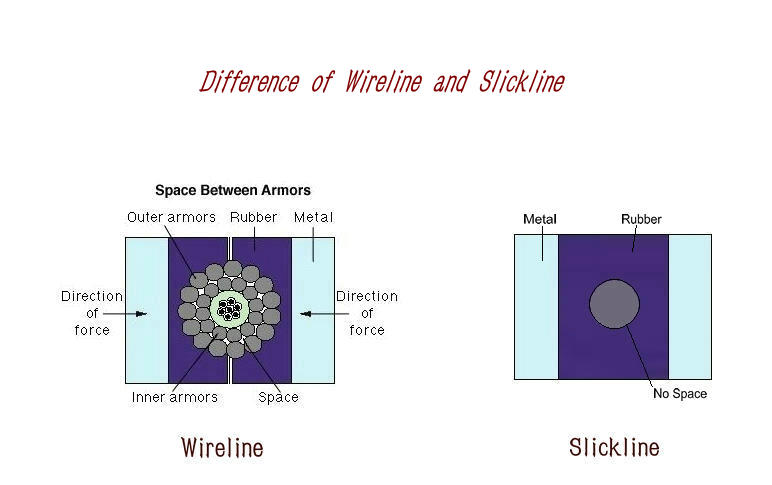

4) Wireline or Slickline Size you applied

5) Upper and Lower Union Required ( Bowen or Otis )

6) Service Environment ( STD or H2S )

7) Working Temperature

What we could find from the picture, there is space between the Inner armors and Outer armors in Wireline Operation. It must inject grease to fill the space to realize full seal. The Grease Injection Cavity locate between the two sets of Wireline Rams Assembly. Therefore, the Single Ram BOP could not applied in Wireline Operation normally cause it could not inject grease into Single Ram BOP.

Normal Guarantee Period

12 months after the clients received the Equipment or 13 months after the commodity is shipped from Chinese Harbor.

Information Required When Inquiry

If you will purchase the whole Wireline PCE, please refer to the Information Required When Inquiry in Chapter《Wireline PCE》.

If you purchase the Wireline BOP separately, the Main Parameter information above mentioned will be asked.