Popular Name:Quick Test Sub / Fast Test Sub / QTS

Quick Test Sub ( QTS ) saves rig time when it’s necessary to make and break the Lubricators to install and remove the Tool String several times.

Normally, Quick Test Sub is inserted above the Wireline BOP at the position of the joint usual opened to insert and retrieve tools from the well. After making the first pressure test to check the integrity of the whole Wireline PCE String, subsequent pressure tests can be made using the Quick Test Sub to verify the integrity of the joint disconnected, rather than having to test the whole assembly.

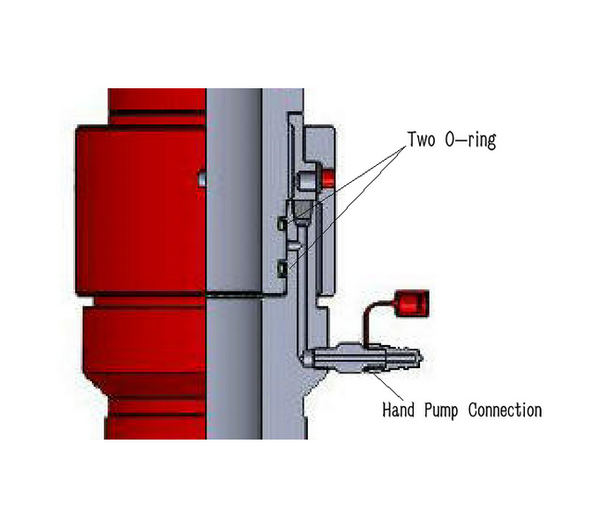

With the Quick Test sub, the connection that is broken can be retested by pressure testing the space between the two O-ring Seals on the Quick Test Sub. This is a small volume and can be pressured up quickly with a Hydraulic Hand Pump from the outside.

A high pressure Hand Pump and 100ft Testing Hose are normal required with the Quick Test Sub no matter Grease and Hydraulic Control Module provided or not.

Feature

1) Saves rig time on pressure test due to design features.

2) Eliminates prospect of contaminating well with test fluids.

3) Eliminates risks of pressure testing with Perforating Guns.

4) Reliable and easy to use.

Main Parameter

1) I.D.

2) Working Pressure

3) Upper and Lower Union Required ( Bowen or Otis )

4) Require Hand Pump and Testing Hose or not

5) Service Environment ( STD or H2S )

6) Working Temperature

Note

1) There are Bowen (Type B), Otis (Type O) and our own Quick Union (Type W) for threaded selective.

2) Additional size available on request.

Normal Guarantee Period

12 months after the clients received the Equipment or 13 months after the commodity is shipped from Chinese Harbor.

Information Required When Inquiry

If you will purchase the whole Wireline PCE, please refer to the Information Required When Inquiry in Chapter《Wireline PCE》.

If you purchase the Quick Test Sub separately, the Main Parameter information above mentioned will be asked.