Popular Name: Coiled Tubing Hanger / Surface Hanger / CT Hanger

Description

The Coiled Tubing Hanger is a long term coiled tubing Hanger consists of a Hanger Cartridge, Slip, Packing Rubber, and Upper Connector. It main apply for gas production in a velocity string. This Coiled Tubing Hanger adopts unique design structure, has the feature of simple operation, safety and reliable suspension.

The upper and lower ends of the Coiled Tubing Hanger are flange connected. During operation, the upper end is connected to the Operation Window, and the lower end is connected to the wellhead Christmas Tree no. 1 valve. When the coiled tubing is placed in position, tighten the jackscrew to seal the coiled tubing manually, then running the Slip into the Coiled Tubing Hanger from the Operation Window, downward press the coiled tubing from the CT Injection Head to lock the slips and hang the coiled tubing. After the coiled tubing be sealed and hanged firmly, cutting the coiled tubing, install the gas tree on the upper of the Coiled Tubing Hanger, and remove the plug in the front of the coiled tubing to resume gas production.

Feature

1) Be used with the Operation Window, simple structure, convenient operation and reliable hanging.

2) Cone slips allow automatic clamp coiled tubing.

3) Upper and lower seals provide reliable sealing.

4) Available in a complete range of sizes and pressure ratings.

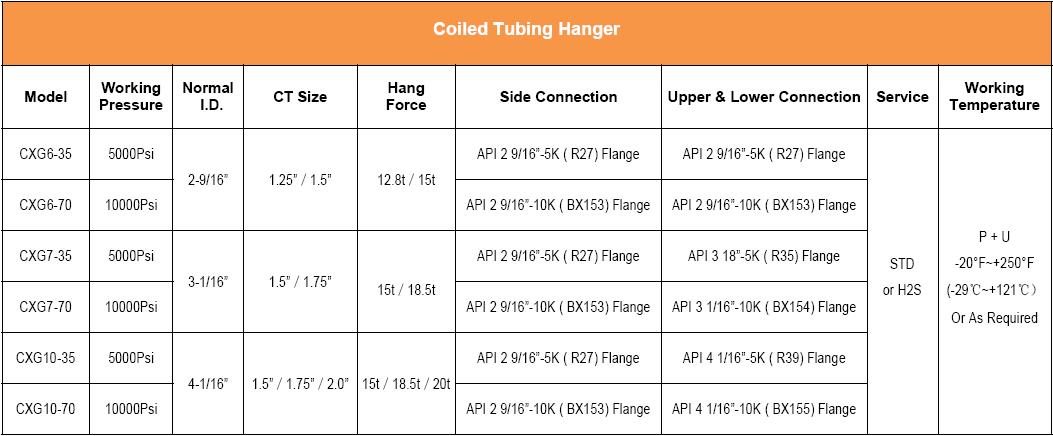

Main Parameter

1) I.D.

2) Working Pressure

3) Coiled tubing size you applied

4) Upper and Lower connection required

5) Service Environment ( STD or H2S )

6) Working Temperature

Note

1) Additional size available on request.

Normal Guarantee Period

12 months after the clients received the Equipment or 13 months after the Equipment be shipped from Chinese Harbor.

Information Required When Inquiry

If you will purchase the whole Coiled Tubing PCE, please refer to the Information Required When Inquiry in Chapter《Coiled Tubing PCE》.

If you purchase the Coiled Tubing Hanger separately, the Main Parameter information above mentioned will be asked.