Popular Name: Coiled Tubing Pressure Control Equipment/ Coiled Tubing PCE/ CT Pressure Control Stack

Coiled Tubing Pressure Control Equipment ( abbr. Coiled Tubing PCE ) is designed to seal the wellhead in the coiled tubing working, so as to prevent the blowout accidents. It could be applied for coiled tubing sand removal, well washing, oil testing, fluid drainage, blockage relief, stage fracturing, gas well completion and other operations. The device is simple in structure, easy operation and convenient in maintenance, which is an ideal equipment for safe and civilized operation in oilfield.

The Coiled Tubing PCE is mainly composed of Side Door Stripper Packer, Riser/Lubricator, Quad Ram BOP, Adaptor Flange, etc.

Feature

1) The design and manufacturing of Coiled Tubing PCE Comply with API Spec-16A, API Spec-6A, NACE MR 0175 and other relevant standards.

2) High Cost-effective.

3) Safety, Reliability and Good Service.

4) Expertly engineered and rigorously tested.

5) Third Party Inspection allowed.

Coiled Tubing PCE String mainly be consist of

1) Side Door Stripper Packer or Two Door Stripper Packer

2) Riser / Lubricator

3) Quad Ram BOP or Combi BOP

4) Adaptor Flange

Note

1) There are Bowen (Type B), Otis (Type O) for Union threaded selective.

2) Additional size available on request.

Package

A Transport Frame is recommended for a set of Coiled Tubing PCE. It could protect the whole Pressure Control Equipment effectively, reduce the damage and loss in transportation. And it easy for transport and lifting. If you purchase the parts separately, It will be packaged in a wooden box or iron box according to the weight and dimension.

Normal Guarantee Period

12 months after the clients received the Equipment or 13 months after the Equipment be shipped from Chinese Harbor.

Information Required When Inquiry

1) Which parts do you needed? And quantity of each parts.

2) I.D. of main parts, such as Adapter Flange, BOP, Lubricators. If these parts have same I.D. , only provide one is OK. If they have different I.D. , please provide each details separately.

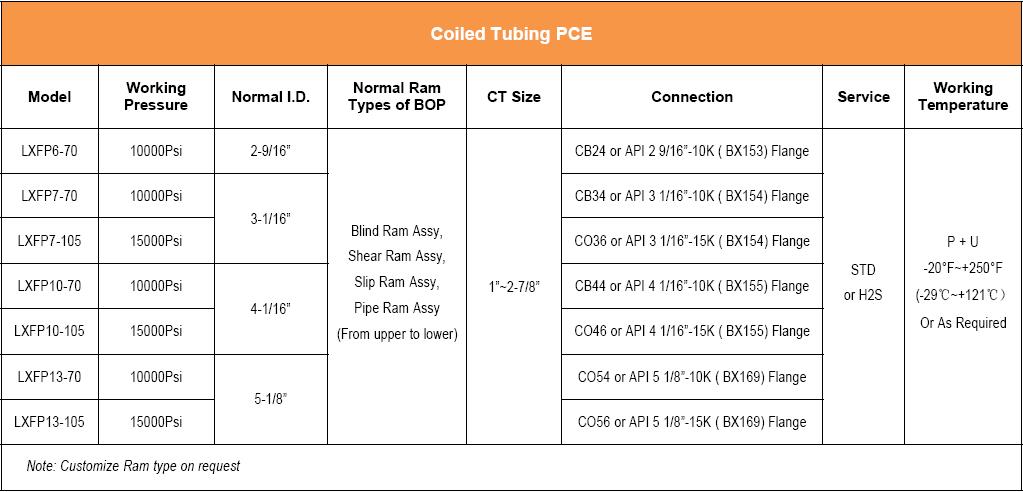

3) The coiled tubing size you will apply when operation.

4) Rated Working Pressure.

5) Quad Ram BOP or Combi BOP you required, and the Rams type you needed of each rams.

6) Required Working Temperature.

7) Service Environment. ( STD or H2S )