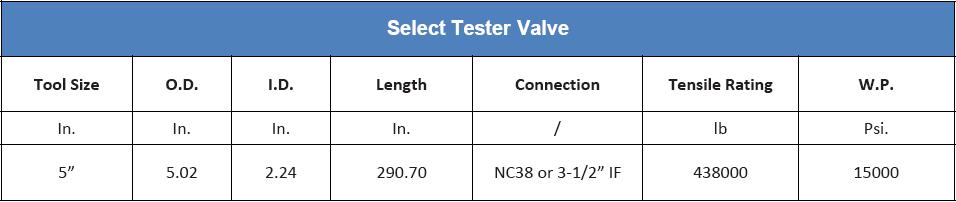

Popular Name: Select Tester Valve

The Select Tester Valve is a full-opening, annulus pressure operated tool. With applied pressure, the tool can be locked open and then returned to the normal operating sequence at any time. The ball valve operates independently of pressure changes from operations such as acidizing and fracturing. This gives the Select Tester Valve greater compatibility and flexibility with other tools in the string.

Features

1) Incorporates advanced materials and processes providing a unique metal-to-metal seal for exceptional gas-holding capabilities.

2) Has undergone extensive five-day qualification testing at 400°F and 15,000 psi including a 16,500 psi burst and collapse test.

3) Allows operator to reverse out/circulate to the lowest point of circulation below the Select Tester Valve. This facilitates well kill operations, saving both time and money.

4) Allows operator to run in or come out of a hole in the open position, enhancing safety and maximizing well control options.

5) Allows operator to spot cushion to the lowest point of circulation below the Select Tester Valve. This improves control of drawdown pressure and reduces recovery of mud and other rathole fluids.

6) Simplifies string design by eliminating the need for a bypass when stinging into or out of a production packer.

7) Maximizes flexibility during well kill operations since the Select Tester Valve can be operated with the packer unset.

Note: When annulus pressure is applied or bled off to zero, it is recommended operating procedure to wait 10 minutes before operating the Select Tester valve again.

Operation

Once the packer is set, pressure is quickly applied to the annulus to operate the Select Tester Valve. This creates the differential pressure that acts across the operating section to move the mandrel down, causing the ball to rotate to the open position. To close the ball, annulus pressure is released to zero. The nitrogen section acts to move the operating mandrel up. This upward travel of the mandrel rotates the ball valve back to the closed position. To activate the lockout feature, the normal operating pressure is increased by 1,300 psi.

This higher level of pressure prevents the operating mandrel from moving up. In this position, the ball valve will remain open when the annulus pressure is released. To reactivate the tool, annulus pressure is once again increased to 1,300 psi above normal operating pressure. This will reactivate the operating section and return the tool to normal operating mode. The lockout feature can be reactivated as many times as desired without having to remove the tool from the well.

1) Other sizes available on request.

2) Meets requirements of NACE-0175 (>175°F)

3) The values of tensile, burst, and collapse strength are calculated with new tool conditions.

4) Pressure rating is the differential pressure at the tool. (Differential pressure is the difference in pressure between the casing annulus and the tool ID.)