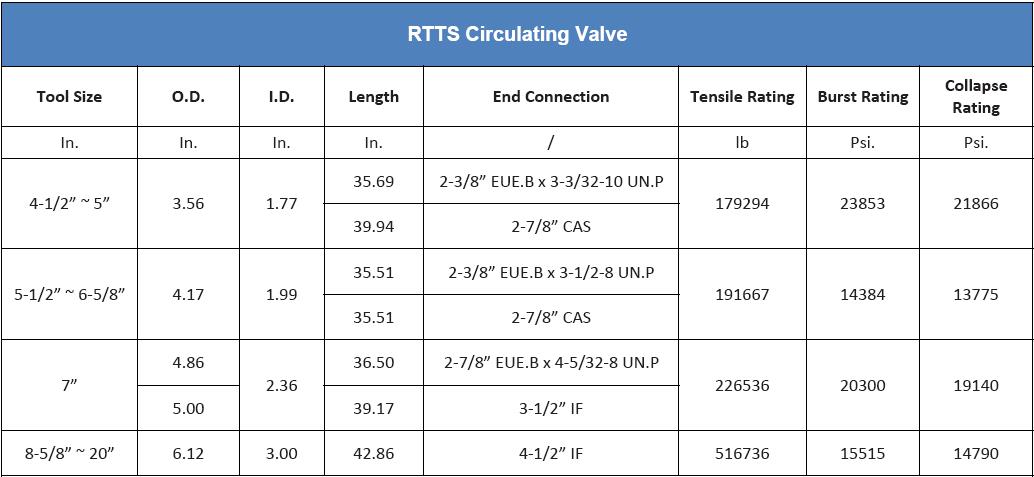

Popular Name: RTTS Circulating Valve

The RTTS Circulating Valve is a locked-open/locked-closed valve that serves as both a circulating valve and bypass. The clearance between the RTTS Packer (or any hookwall Packer) and the casing ID is relatively small. To reduce the effect of fluid-swabbing action when the tool is run in or pulled out of the hole, a packer bypass is generally used.

The RTTS Circulating Valve can be run directly above the packer body or further up the workstring. When placed in the hole, the valve must be in the locked-open position. The J-slot in the packer-body drag block (or drag sleeve) must also be placed in the unset position.When the RTTS Circulating Valve is opened to come out of the hole, the tubing is lowered, turned to the right, and picked up.

Features

1) The valve can be locked closed when the packer is unset to reverse fluid around the bottom of the packer.

2) The tool’s full opening allows tubing-type guns and other wireline equipment to pass.

Operation

The RTTS Circulating Valve is automatically locked in the closed position when the packer is set. During testing and squeezing operations, the lock helps prevent the valve from being pumped open. A straight J-slot in the locked-open position can be used with the straight J-slot (optional) in the packer body. This combination eliminates the need to turn the tubing to close the circulating valve or reset the packer after the tubing has been displaced with cement.

1) Other sizes available on request.

2) The values of tensile, burst, and collapse strength are calculated with new tool conditions.