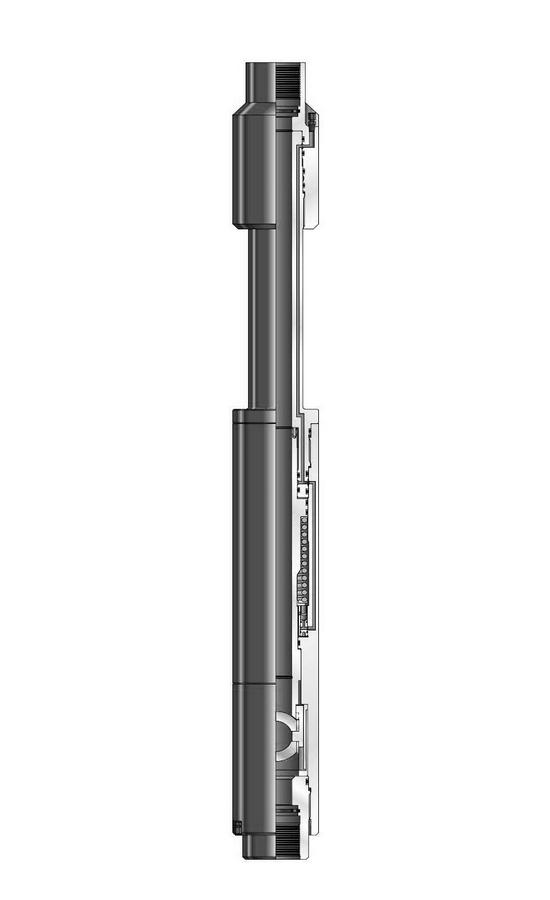

Popular Name: Super Safety Valve

The Super Safety Valve (SSV) is a master valve used for testing operations from jack-up or land rigs. The Super Safety Valve is installed in the test string so that a BOP ram can be closed on the ramlock sub located in the top section of the valve. The annulus is then protected by the BOP rams, and the test string is protected by the Safety Valve. The Super Safety Valve is capable of cutting wireline and 1.5” coiled tubing. If equipped with a cutter ball, it is capable of cutting 2” OD, 0.125” wall coiled tubing using a nitrogen dome charge or by applying balance line pressure.

Features

The Super Safety Valve is controlled by two hydraulic lines and contains a chemical injection port for injecting chemicals at the valve body further downhole to an injection sub or to actuate a subsurface safety valve. The valve is held open by maintaining hydraulic pressure on the control line. The SSV is designed to close by spring force but incorporates a nitrogen dome charge chamber to provide increased closing force and to lessen the time required for closing. This feature gives the valve the ability to cut wireline and coiled tubing without adding balance line pressure.

1) Normally closed/fail-safe

2) Maintains pump-through capabilities at all times

3) Nitrogen dome charge for fast response

4) Capable of cutting 1.5” coiled tubing, or if equipped with a cutter ball 2” OD, 0.125” wall thickness coiled tubing

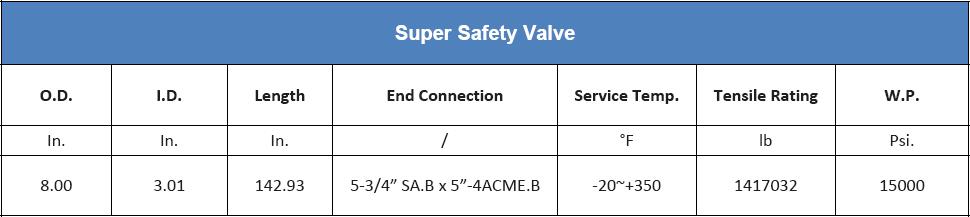

5) Small 8” OD fits inside 9 5/8” casing

1) Other sizes available on request.

2) Meets requirements of NACE-0175 (>175°F)

3) The values of tensile, burst, and collapse strength are calculated with new tool conditions.

4) Pressure rating is the differential pressure at the tool. (Differential pressure is the difference in pressure between the casing annulus and the tool ID.)