Popular Name: Hydraulic Circulating Valve

The Hydraulic Circulating Valve serves as a bypass around the packer or as a circulating valve to circulate a well after testing. When run below a closed valve, the tool serves as a bypass around the packer and helps relieve pressure buildup below the closed valve when it is stung into a production packer.

When run above a closed valve, the tool can be used as a circulating valve when the workstring is picked up.

Features

1) Permits passage of wireline tools through its full-opening bore

2) Requires no pipe rotation to operate

Operation

Bypass ports close when weight is set down and reopen when weight is lifted.A hydraulic metering system provides a 2 to 3-minute delay in closing after weight is applied. This delay allows either the RTTS Packer to be set or the test string to be stung into a permanent packer before the bypass ports close. The ports re-open without a time delay.

During stimulation work, the latching piston adds a downward force on the circulating sleeve to help keep the valve closed. Operation of the valve is the same whether it is used as a circulating valve or as a bypass. No torque is required. Weight is applied to close the tool, and the workstring is picked up to re-open it.

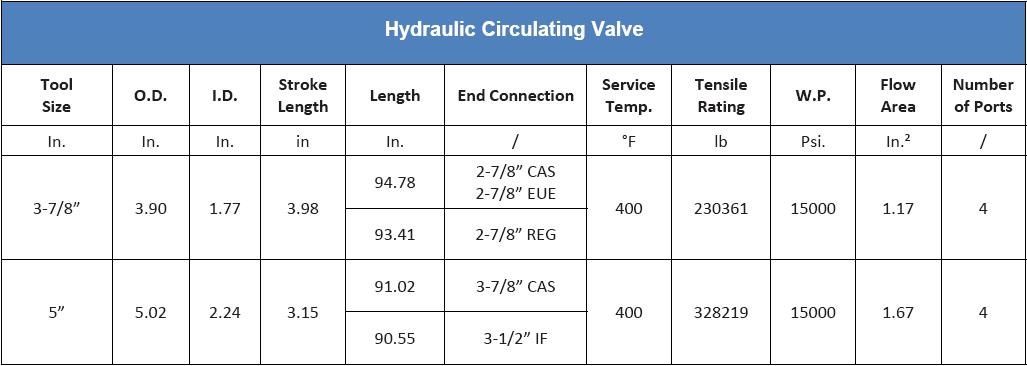

1) Other sizes available on request.

2) Meets requirements of NACE-0175 (>175°F)

3) The values of tensile, burst, and collapse strength are calculated with new tool conditions.

4) Pressure rating is the differential pressure at the tool. (Differential pressure is the difference in pressure between the casing annulus and the tool ID.)