Popular Name: Lubricator / Wireline Lubricator / Integral Lubricator

The Lubricator provides the downhole tool string with a pressure buffer zone and a transition zone through which the instrument passes. According to the needs of the site, multiple Lubricators can be connected in series.

The Integral Lubricator is a pressure containing cylinder used when performing wireline operations. Its purpose is to allow the Wireline Tool String to be raised above the wellhead prior to and after wireline operations, thereby enabling the wellhead valve to be opened and closed, allowing entry and exit from the well bore. This type of Lubricator is usually recommended service in working pressure≧10000Psi.

Generally, it requires the total length of Lubricator sections at least 1000 mm longer than downhole string tool.

An optional Bleed-off Port may be incorporated into the lubricator assembly. This involves a ported NPT-1/2” sub between the Lubricator tube and the bottom Quick Union.

Feature

1) One piece forged Pipe Body.

2) Assemblies available in custom lengths and sizes.

3) Available with customized top and bottom connections.

4) Working pressure and service ratings available.

5) Industry-standard unions.

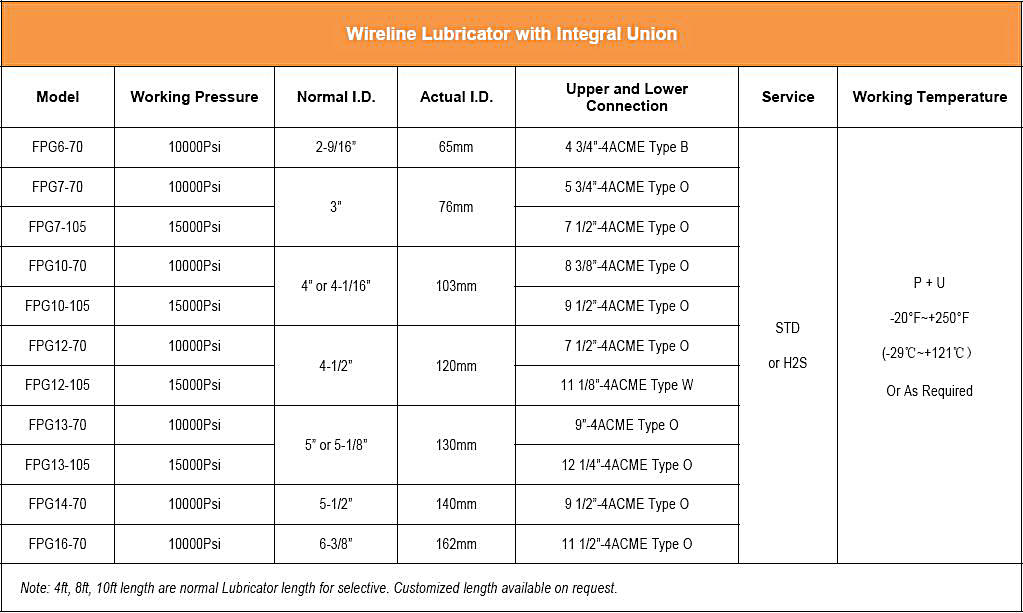

Main Parameter

1) I.D.

2) Working Pressure

3) Upper and Lower Union Required ( Bowen or Otis )

4) Service Environment ( STD or H2S )

5) Working Temperature

Lubricator with Integral Union

Note

1) There are Bowen (Type B), Otis (Type O) and our own Quick Union (Type W) for threaded selective.

2) Additional size available on request.

Normal Guarantee Period

12 months after the clients received the Equipment or 13 months after the commodity is shipped from Chinese Harbor.

Information Required When Inquiry

If you will purchase the whole Wireline PCE, please refer to the Information Required When Inquiry in Chapter《Wireline PCE》.

If you purchase the Integral Lubricator separately, the Main Parameter information above mentioned will be asked.