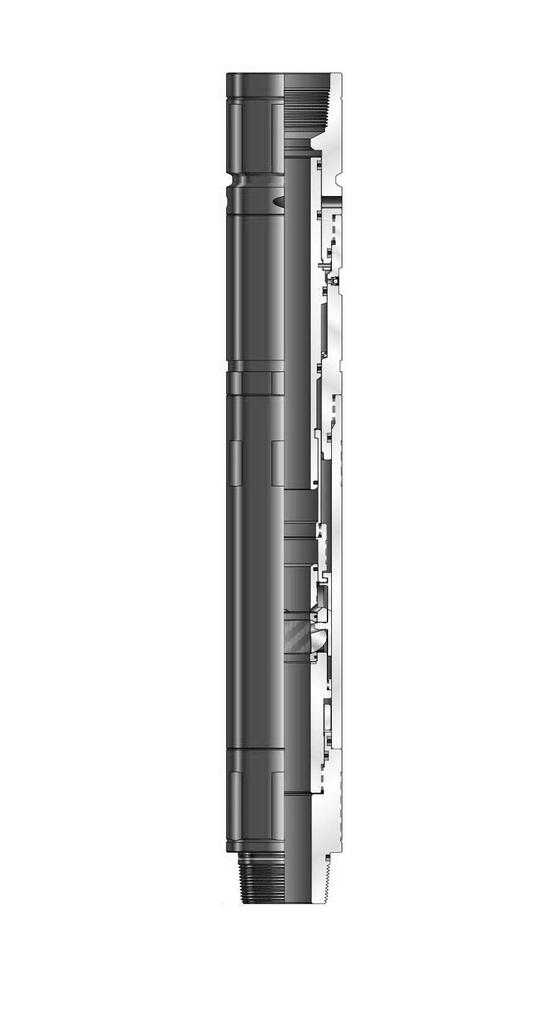

Popular Name: Rupture Disk Safety Circulating Valve / RD Safety Circulating Valve

The Rupture Disk Safety Circulating Valve (RD Safety Circulating Valve) functions as both a safety valve and circulating valve. The tool functions as a safety valve when the annulus pressure reaches a predetermined value. At that pressure, the valve isolates the workstring below the tool and establishes communication between the annulus and the workstring above the tool. This tool converts into a circulating valve when the ball valve section is removed.

Features

The Rupture Disk (RD) Safety Circulating Valve is composed of three major sections:

1) The power section consists of a power mandrel case and rupture disk that is available for a wide range of pressure applications. The rupture disk bursts at a predetermined pressure, allowing annulus pressure to be applied to a differential area on the power mandrel. The power mandrel moves down, first pushing the ball valve closed, and then opening a set of circulating ports.

2) The circulating section consists of a set of ports that are initially sealed by the power mandrel. When the rupture disk bursts, the power mandrel moves down, exposing the ports that allow communication between the annulus and workstring.

3) The safety valve consists of a ball valve, operating pins, and collect fingers. As the power mandrel moves down, the operating arms close the ball valve. The collect fingers expand, allowing the power mandrel to continue traveling down to open the circulating ports.

Operation

Before the Rupture Disk (RD) Safety Circulating Valve is used, the operating pressure is calculated for selecting the proper rupture disk pressure rating. Required information includes mud weight, testing depth, bottomhole temperature, and maximum annulus pressure. When the Rupture Disk (RD) Safety Circulating Valve is run with an annulus pressure-operated valve, the safety valve operating pressure should be kept 1,000 psi above the operating pressure of the tester valve.

1) Other sizes available on request.

2) Meets requirements of NACE-0175 (>175°F)

3) Full sour gas service

4) The tool can be converted to a higher pressure rating by changing out to a 5-1/4” circulating case.

5) The values of tensile, burst, and collapse strength are calculated with new tool conditions.

6) Pressure rating is the differential pressure at the tool. (Differential pressure is the difference in pressure between the casing annulus and the tool ID.)