Popular Name:Pressure-Responsive Multi-Service Valve / PR Multi-Service Valve

The Pressure-Responsive Multi-Service Valve (PR Multi-Service Valve) is a full-opening, annulus pressure-operated valve for use in cased holes. This tool can be run as a surge valve or back pressure valve.Top and bottom PR Multi-Service Valves are run at the same time to form a surge chamber. This surge helps clean debris from the perforations before a stimulation treatment, sand control treatment, or flow test. Potential for sudden pressure surge is provided when two Multi-Service Valves are spaced apart in the tubing string to form an atmospheric air chamber. When the bottom ball valve is opened, solids forced into the perforations are swept into the air chamber by the fluid stage.

Features

1) Requires no pipe manipulation to operate

2) Achieves more effective surge because of the instant ball opening

3) Creates the required air chamber volume by spacing valves

4) Allows circulating or spotting of well fluid when surging is complete

5) Permits through-tubing operation through full-opening ID

Operation

As PR Multi-Service Valves are run into a well, the ball valves are in a closed position, and atmospheric air is trapped between the valves. The bottom valve is opened by the operating piston, which has one side exposed to the annulus pressure above the packer and the other side exposed to pressure below the packer. After the packer has been set, pressure applied to the annulus moves the piston downward to pull the ball into the open position. The locking dogs drop into a groove, keeping the ball in the fully open position. As long as the tubing pressure is equal to or greater than the annulus pressure, the top valve is kept closed when the lower valve is operated.

Before the top valve can be opened, tubing pressure must be relieved while the annulus pressure is maintained. The top PR multi-service valve also contains locking dogs that lock the ball in the fully open position. After the valves have been opened, circulation can occur with the packer unseated. Opening pressure is controlled by the shear pins. The number and type of shear pins can be adjusted to raise or lower the operating pressure.

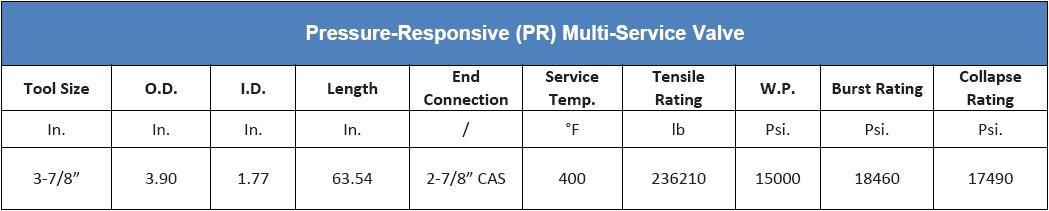

1) Other sizes available on request.

2) Meets requirements of NACE-0175 (>175°F)

3) The values of tensile, burst, and collapse strength are calculated with new tool conditions.

4) Pressure rating is the differential pressure at the tool. (Differential pressure is the difference in pressure between the casing annulus and the tool ID.)